About Us

What We Do

Southcoast Laser is a subsidiary of Southcoast Marine Products which is one of the largest manufacturers of marine hardware that varies from simple grab handles to bow rails and foldaway seats. The focus of Southcoast Laser is to cut and manufacture parts that are further processed by Southcoast Marine Products through our laser capabilities.

Our Work

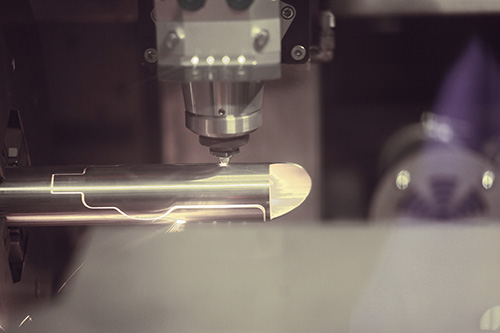

We currently utilize two laser systems, a 6,000-watt Bystronic and another 10,000-watt BLM Group lasers, to cut stainless steel sheets or tubes into desired parts that will be further manufactured into completed products. Our system is based on the CAM/CAD file system and those files will be required before we are able to process any parts.

Why South Coast Laser?

The better question might be, “Why wouldn’t I use Southcoast Laser?”. Southcoast Laser and Southcoast Marine Products have both been family owned and operated since 1973. We have the third generation of the family taking part in the company and becoming very involved to ensure the quality of our products and our services are always excellent.

Our company has been family owned and operated since its founding back in 2000 and has manufactured hundreds of thousands of parts for the marine industry. All our manufacturing, cutting, and bending processes are done in house and rarely outsourced and we are dedicated to providing high quality products to our customers around the United States.

While most of our capabilities are centered around using laser technology to cut flat sheet metal into the desired products, we do also possess the capabilities of tube processing such as making rails, grab handles, and bow rails to name a few.

The design of parts and tubing takes place in a three-dimensional CAM/CAD program so that we are able to exploit and expose all sides of the part to help ensure accuracy. This CAM/CAD program system is also our primary method of designing our own custom parts and hardware and is also preferred.

While most of the material we work with is 304 and 316 Stainless Steel, we also have the capabilities of working with mild steel and aluminum as well.

At our facility we operate two lasers, a 6,000-watt Bystronic 3015 and a 10,000-watt BLM Group laser LC5. We also have two operation break presses, one also being a 150-ton Bystronic press and the other being a 120-ton strippit LVD press.

We are also installing a new BLM Group tube bender to give us extreme accuracy with it comes to manufacturing rails and pipes.